PFI’s New Injection Press

Watch as our brand new Injection Press is moved into place and installed in our Hazelwood, MO warehouse!

PFI is adding to our large press injection molding capabilities with a new 1,200 ton press. This is our third press larger than 1,000 tons! This new press adds significant production capacity as well as flexibility to manage several key glide products such as Cool Glide 20/20

and ice barrel components for our Iceman retail barrel coolers.

It also allows us to better respond to customer needs while providing better control of overtime and outsourcing which helps us keep costs to our customers low.

The lower floor of the warehouse had to be fortified with additional support beams to withstand the 1,200 ton press moving overhead on the main floor.

The injection press is pictured here just before it enters the warehouse. The garage door had to be widened to accommodate the width of the press. The day of the move also happened to be the coldest day of the year (-5° F) as the "polar vortex" settled over the Midwest.

The heavy lifting was done by a small robot (pictured above under backside of press) that was controlled by someone on the moving crew.

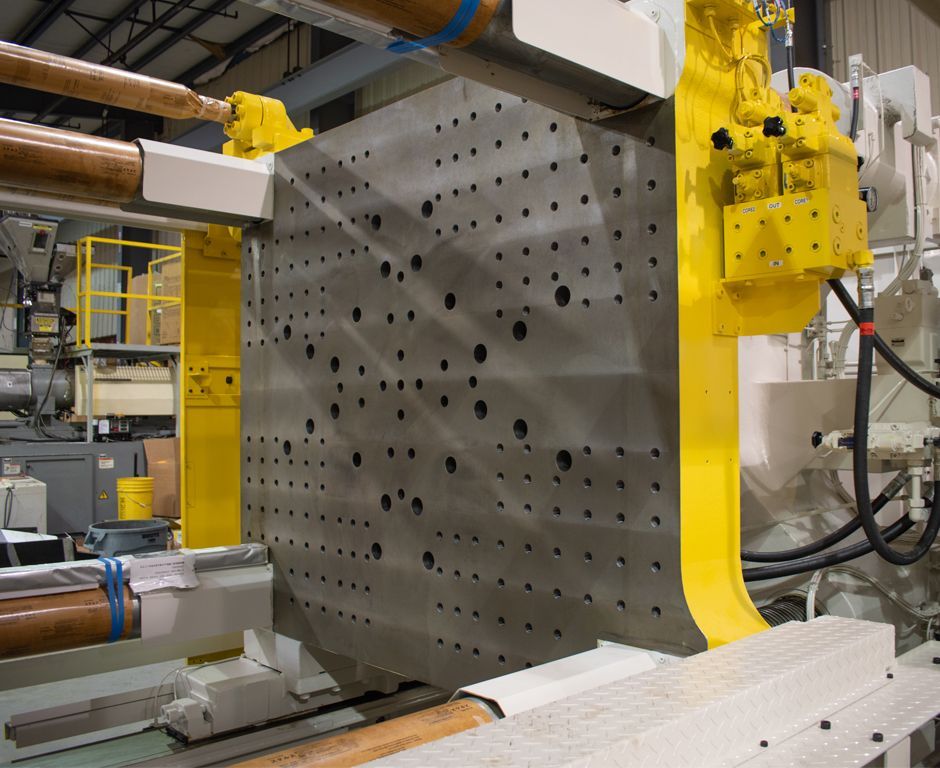

The Injection Press all moved into place.

Close up of the actual press.